(Krono Super Natural)

| Laminated flooring is made up of a high-density fibreboard (HDF) core; a melamine-impregnated decor layer which is a photographic reproduction of a real wood or tile floor; and a highly-resistant synthetic resin-treated cellulose protective overlay on top to give the floor the protection and durability required. Under the HDF core is a balancing laminate which improves the structural stability of the board and prevents moisture from getting into the HDF core once the floor has been laid. Under immense pressure and heat this 'sandwich' is bonded together to form a huge sheet of flooring which is then cut into smaller boards, the edges of which are then profiled so that the boards can be locked together without the need for any adhesive. During the production process surface finishes such as embossing and texturing are applied. |

| The 1Clic2Go system simply clicks together for easy installation, especially in tricky areas like radiators and doorways. You'll hear a click when the end section joints locate correctly and the high stability of the system prevents the joints from coming open. Have a look at the installation tab to see a video of just how easy it is to put a floor together. |

| The high-density fibreboard (HDF) core is a wood product formed by breaking down low grade timber and forest thinnings into wood fibres, combining them with wax and resin, and then forming panels under high temperature and pressure. The result is an incredibly strong and stable product suitable for a very wide variety of uses. The density of HDF varies between 800 - 1450 kg/m³, the choice of density being the factor in a floor that determines the toughness of the floor for the grade of flooring required. Put simply, the higher the density, the greater the impact resistance and the heavier the use the floor can cope with. Krono Original floors are environmentally-friendly as standard and are made from 70% wood sourced from sustainably managed forests. The entire production chain from raw materials through to the finished product has been certified and is regularly inspected by independent experts. |

| The surface of a Krono Original floor is protected from moisture by the melamine resin impregnation of the decor paper and the overlay. That doesn't make a floor suitable for use in bathrooms or wet areas but it does stop moisture from penetrating the top surface of the floor and causing the HDF core to swell and subsequently deteriorate. |

| The surface of a Krono Original floor is therefore non-porous and resistant to spills. Even red wine, oil and jam won't affect it, so don't panic - they're easily removed. Don't however use floor polish as it can't be absorbed by the floor and you'll end up with a skating rink. The floor is also resistant to abrasion and tough. Heavy furniture won't leave an imprint although ideally castors and furniture legs should be protected with felt pads. |

| Naturally it’s important that your floor stays as clean and free from bacteria as possible. Whilst bacteria can't be seen, the kinds of harm it can cause if it's not eliminated are well known, for instance heightened allergies and disease. For this reason Krono Original floors incorporate A.B.C. Anti-Bacterial Coating as standard. |

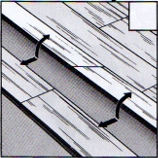

| The authentic emossed surface finish brings out the grain on all our Krono Super Natural floors and gives a natural look and feel to a floor. The quality and surface feel of these floors is created by the unique embossing of the laminate paper during the production process. |

| Our Krono floors incorporate a V-groove around all four edges of a board. It's formed by each edge of the board being bevelled so when two boards interlock, a V-groove is formed, accentuating the look and feel of a planked floor. |

| Krono Super Natural floors are designated Class 23 for residential use which means that they are suitable for heavy domestic use in all rooms except bathrooms and wet areas, so bedrooms, guest rooms, living rooms, dining rooms, kitchens, corridors, home offices are no problem. |

| Krono Super Natural floors are also designated Class 32 for commercial use which means that they are suitable for normal loads and traffic in areas such as hotel rooms, offices, meeting rooms, waiting rooms and boutiques. |

(1Clic2Go Pure)

Your Krono floor is really simple to install!

A bit of planning, a bit of care and your floor will look as though it's been laid by a professional!

First of all

1. Take up your old carpet or carpet tiles. Do not lay your new floor on a carpet or any other kind of soft floor covering. If your existing floor covering is linoleum, pvc tiles, ceramic tiles or any other kind of hard floor covering, then you can lay your new floor on top providing the surface of your existing floor covering is not damaged in any way.

2. If you're replacing the skirting boards, remove those as well.

Before you do anything else

1. Make sure your sub-floor is clean. Brush or vacuum up anything that will prevent your new floor from lying flat on your sub-floor.

2. Make sure your sub-floor is flat. Get a two metre straight edge, lay it across the floor and if there is more than a 2mm gap between the straight edge and the sub-floor, you will need to rectify this before laying your new floor.

3. If your sub-floor is concrete and it's just been laid, make sure the room's properly ventilated and allow it to dry out for at least a week for each 10mm of concrete up to 40mm, and for at least two weeks for each 10mm of concrete over 40mm. With concrete screeds the residual moisture content of the sub-floor should not exceed 75% rh when using a hygrometer.

4. If you have underfloor heating, make sure that the heating-up phase has been properly carried out before laying your new floor. Under no circumstances lay your floor if the surface temperature of the concrete sub-floor exceeds 27°C.

5. If your sub-floor is wood, make sure

(a) that any loose boards are nailed down properly and no nail heads are protruding

(b) that the moisture content of the wood does not exceed 10%

(c) that any cavity underneath the sub-floor is properly ventilated

6. Bring your new floor into the room where you're going to install it. Leave the floor in the packs for at least 24 hours and don't open them until you're ready to lay the floor. The ideal environment for laying a floor is a temperature of 18°C and relative humidity of 45 - 60%.

Under-floor heating

Krono floors may be laid over under-floor heating but you must ensure that the following guidelines are adhered to:

(1) Electric under-floor heating systems are able to supply an almost instantaneous heat to the floor which warms up the floor over a very short space of time and can cause tensions within the floor. You can however lay a Krono floor over electric under-floor heating providing that

(a) the maximum temperature of the heating system does not exceed 27°C at the point of contact with the floor

(b) the maximum temperature is reached in gradual stages by gentle increments over a period of time - correspondingly if the under-floor heating system is to be switched off, the minimum temperature should be reached in gradual stages by gentle increments over a period of time

(c) the cable carrying the heat is protected from direct contact with the floor

(d) the under-floor heating system is operating at all times thereby avoiding any dramatic increases or decreases in temperature which in turn will limit the amount of expansion and contraction that may take place

(2) With hot water pipe under-floor heating systems, the sub-floor slab should be activated to normal living temperatures for a minimum of 21 days and the maximum temperature maintained for at least a week. The temperature should then be reduced by 5°C per day until the sub-floor temperature is between 16°C and 18°C at which point the floor can be installed. After installation, the temperature of 16°C and 18°C should be maintained for 3 - 4 days before it is gradually increased over a further 3 - 4 days to the recommended sub-floor surface temperature.

Tools

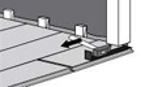

One of our installation kits is a great help when it comes to laying your floor.You get some 10mm plastic packers which give you the correct gap around the edge of the floor whilst at the same time keeping the floor in position while it's being laid. Once you finished laying the floor though, make sure you remove these packers.

You also get a plastic knocking block which you should use with a hammer to tap the boards tight up to each other.

Finally you also get a pull-bar which is used to pull the last board in a row as well as the boards in the last row in the room tight into each other. Obviously you can't use the knocking block in these instances so you hook the lip of the pull-bar over the edge of the floor and use the hammer on the other end of the pull-bar to pull the floor in tight.

Apart from the 'specialist' tools in the installation kit, you will also need a hammer, a saw (either a fine-tooth handsaw or a jigsaw or a cross-cut saw), a set square, and a tape measure and pencil. A useful tip is to use a downward-cutting blade on a jigsaw.

Underlays

All the underlays available with this floor are shown in Related Products below

You should make sure that wherever a damp-proof membrane is used under the floor that the edges of the DPM go up the wall to be hidden behind the skirting boards once they are fitted.

The Basix Comfort White underlay is a 2mm white polyethylene foam underlay with excellent sound insulation properties. It absorbs minor floor imperfections and is suitable for underfloor heating. It's lightweight and simple to install. Bear in mind that to comply with the manufacturer's warranty you will need to use a separate damp-proof membrane wherever the sub-floor is concrete.

The Basix Premium Silver underlay is a 3mm green polyethylene foam underlay with a built-in damp-proof membrane with an overlap for joint sealing protection, and excellent sound reduction properties. As with the Basix Standard White underlay, it absorbs minor floor imperfections, it's suitable for underfloor heating and it's simple to install.

The Basix Ultra Silver underlay is a 3.5mm high-density recycled rubber underlay with an aluminium vapour barrier. It has substantial sound reduction properties and is a high-density foam rubber for enhanced compressive resistance. It absorbs minor floor imperfections and it's simple to install but although it is suitable for water-piped underfloor heating systems, it's NOT suitable for electric underfloor heating systems.

The Basix Foamboard Green underlay is 5mm thick, dense, rigid fibreboard panel (600mm x 856mm) which is loose-laid across the sub-floor. It reduces noise in rooms considerably and it limits heat-loss through the floor. It's also a natural product and easy to install. Bear in mind that to comply with the manufacturer's warranty you will need to use a separate damp-proof membrane wherever the sub-floor is concrete.

Expansion and contraction

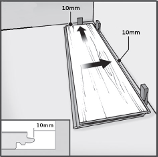

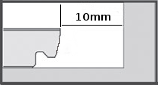

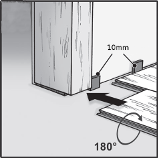

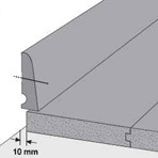

Wood will move depending on ambient temperature and humidity so you must allow for any expansion and contraction to take place otherwise you will find the floor lifting up in the most unlikely places. You make this allowance by leaving a 10mm gap around the edge of the floor and the 10mm plastic packers in the installation kit are ideal for this. Don't forget to allow 10mm around every edge of the floor - for instance, around radiator pipes and at doorways amongst others. Don't worry about this 10mm gap being visible when you've laid the floor - we'll deal with finishing off the floor later.

A guide for this allowance for expansion and contraction is 1mm per metre of flooring on each edge of the floor so be careful if your floor is greater than 10 metres in any one direction. Watch out also if you're running a floor through a doorway into another room without a break and the combined length of flooring in the two rooms exceeds 10 metres. In these situations you can either increase the 10mm allowance - for example, if your expanse of floor is 14 metres long, allow for a 14mm gap on both sides of the room - or put in an expansion profile somewhere, for instance across a doorway.

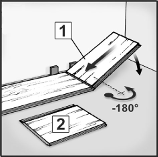

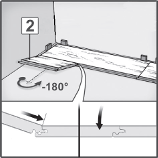

The 1Clic2Go Pure interlocking joint

The 1Clic2Go Pure interlocking joint used in our Krono floors is really simple to use. Have a look at the video and see how easy it is to put a floor together.

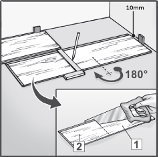

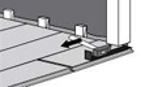

It's worth mentioning here that if you need to take up some flooring which has already been laid, lift up and disengage the row and then slide the boards apart as shown in the diagrams below. Do NOT lift up the boards to separate them - you will damage the end joint.

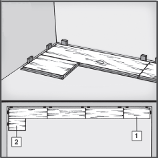

Laying the floor

Although in theory you can start laying your floor wherever you want, it's best to start in the left-hand corner of the room and work from left to right across the room. Doorways and radiator pipes can present a bit of a problem so give some thought as to how you're going to cope with them before you start laying the floor.

Roll out the underlay and don't forget to use a separate damp-proof membrane on a concrete sub-floor if there isn't already one built into it.

You should lay the tongue side of the floor up against the back wall and put the plastic packers between the tongue and the wall to get the right gap for expansion/contraction. You'll see that the tongue is proud of the top surface by 2mm so make sure the skirting or beading you're using around the edge of the room more than covers the overall gap of 12mm. If it doesn't, shave off the tongue which will then leave just the 10mm gap formed by the plastic packers.

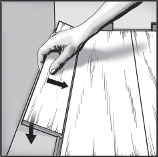

When you get to the end of the row, you've got two options. The simplest way is to measure the distance between the edge of the last board you've laid and the wall; deduct 10mm for the expansion/contraction gap; and then simply cut the board to length.

Alternatively, turn the board you're going to cut to length the wrong way round, keeping the decorative surface uppermost, and lay it up against the leading edge of the last board you've laid as shown in the diagram.

Place the board tight up against the right-hand wall and insert a 10mm plastic packer so you get the correct expansion/contraction gap.

Using a set square, draw a line across the board in line with the leading edge of the previous board (as shown in the diagram above), cut the board to size and put it in place using the pull-bar if necessary.

Take the offcut from the end of the first row and unless it's a ridiculously short length, use it to start the next row, not forgetting to put a 10mm plastic packer between it and the left-hand wall.

The last row

When you get to the last row, you will almost certainly have to cut the boards lengthways to get them to fit between the wall and the floor you've already laid. The simplest way to do this is to measure the gap, deduct 10mm for expansion and contraction and cut the board to size. You'll be surprised how often the walls of a room are slightly out so take the measurement at both ends of the board and in the middle as well if necessary.

The last row can be a bit fiddly to fit and this is where the pull-bar is really useful so use it on the side and the header joints wherever necessary. If you have any trouble getting the boards in the last row in place, shave the lip off the front edge of the groove with a wood chisel and glue the joints together using a PVA adhesive.

Doorways

Doorways take a little bit of thought, especially if you're running the floor through from one room to another without a break, but providing you plan ahead, they shouldn't be that much trouble.

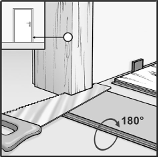

Before you start laying the floor, or at the very latest before you get too close to a doorway, get an offcut of the floor and the underlay, put them up against the door jamb and then use a handsaw to undercut any architraves and door linings as shown in the diagram below. Clear out any debris so the floor can move freely under the door frame once it's installed. Also check to make sure the floor with the underlay underneath can move freely under the door itself and if necessary undercut the door as well.

If you are planning to run the floor through the door without a break, you will need to cut the door linings and the architraves all the way through. If however you're stopping the floor at the doorway, just cut the linings as far as you're taking the floor.

You should end up with a gap at the bottom of the door jamb which allows you to slide both the floor and the underlay underneath, AND which at the same time gives you the 10mm expansion and contraction gap, now hidden underneath the door lining.

Cut the boards to shape when you reach the doorway, not forgetting the 10mm expansion/contraction gap, so they fit under the door jamb. You may find it difficult to click the boards in place around a doorway so chisel off the leading edge of the groove and use a PVA adhesive to glue the boards together wherever necessary. Use the pull-bar and knocking block to pull the boards tight to each other.

Use a threshold section such as our matching 'T' sections, matching ramp sections or matching end sections shown in Related products below, wherever the floor butts up to a different floor covering and don't forget to allow for the 10mm expansion/contraction gap.

Radiator pipes

Have a look at the installation tab on the radiator pipe covers page for tips on cutting the floor around radiator pipes and fitting the covers.

Finishing off

Once you've finished laying the floor, make sure you remove all the 10mm plastic packers.

If you removed your skirting boards at the outset and you're either refitting them or replacing them with new ones, make sure that the thickness of the skirting being fitted is at least 12mm. Any less than that and the 10mm expansion and contraction gap may become visible should the floor move for some reason.

Where the existing skirting boards have been left in place and you've allowed the 10mm expansion and contraction gap between the skirting and the floor, you will need to use a beading to cover the gap. Scotia beadings are available in white or to match your chosen floor.

Have a look at the installation tab on the scotia beading page for tips on fitting it.

Do NOT under any circumstances pin or glue any beading or skirting to the floor. The floor must be allowed to move freely under the skirting or beading at all times.

Your Krono floor is really easy to look after!

A bit of care and it will look good for years to come!

Looking after your floor

The toughness and resilience of your floor will keep it looking great for years to come. Wear and tear from everyday use is rarely seen. Surface dirt can be removed with a cloth or a vacuum cleaner and scuff marks and difficult stains can easily be got rid of with a slightly damp cloth.

Krono floors are light-resistant to level 6 on the Blue Wool Scale according to DIN 13229 meaning that the colour of your floor will always stay the same.

Do's

Your floor's biggest enemy is grit and the smaller the grit, the worse it is. The first thing you must do therefore is to put an entrance mat inside every external door to encourage people to wipe their feet, and hopefully that will prevent any problems from arising. If possible, have one outside as well and also, don't forget to clean your mats every so often.

Use felt pads under furniture legs to stop any unforeseen scratching and put castor cups under the castors on chairs and sofas. Please note that you can void your warranty if you do not use felt pads and damage results. Office chairs with wheels should use Class W soft rubber castors in accordance with DIN 68131.

Always lift heavy furniture when you're moving it around the room.

Clean your floor regularly. Use a brush or vacuum cleaner to get all the loose dirt off the floor whenever needed. If necessary, use a very slightly damp cloth or mop but don't use too much water and always make sure your floor is wiped dry afterwards. Smear marks can be difficult to get rid of.

Wipe up any spilled liquids as soon as possible.

Keep the ambient temperature to 18 - 20°C whenever possible.

Don't's

Don't leave water or any other liquid lying around on your floor for any length of time.

Don''t use a wet mop to clean your floor. Just use a very slightly damp mop.

Don't use an abrasive cleaner. This will damage the finish of your floor.

Don't let sharp or abrasive objects come into contact with your floor.

Don't slide heavy furniture across your floor.

Don't wear stilettos, especially ones with worn heels.

Repairing your floor

Small nicks and scratches can be repaired using a colour-matched filler but larger areas may mean that some boards need replacing. You can do this by taking up the floor as far as the damaged boards; putting in new boards; and then relaying the original undamaged boards. It's also perfectly possible and relatively straightforward to replace a damaged board without having to take up any of the surrounding floor. Give us a ring on 01782 791401 and we'll talk you through it.

General

All goods are guaranteed from the date of delivery for the period and under the conditions warranted by Krono Original. If any goods are found to be defective during the guarantee period and providing such defects have not occurred through incorrect installation, usage or maintenance procedures, or through the liability of other products or persons, we will at our discretion either rectify or replace the defective part of the goods or refund a corresponding proportion of the original price in accordance with the manufacturer's warranty. All goods should be carefully checked for any visible defects both before and during installation. Any goods which are installed in spite of such defects are not covered by the guarantee. Under no circumstances shall we be liable for any consequential loss whatsoever in the event of any claim arising under a guarantee.

Krono Original Warranty:

Provided the pre-requisites stated hereafter are observed, Krono Original guarantees that the decor layer of their floors will not wear off within the abrasion warranty period shown for each individual floor, the warranty period beginning from the date of purchase.

Pre-requisites:

- the laminated floor must be installed and maintained correctly in accordance with the Krono Original installation and maintenance instructions

- the laminated floor may only be used according to the recommended level of intensity shown for each floor

- the warranty does not cover physical damage - e.g. damage done to the floor by dragging or dropping hard objects

- the warranty does not cover damage caused by moisture ingress

- a large protective mat must be provided at all entrance areas

A claim under the warranty may be made where when:

- the decor layer has worn off in an area of at least one square centimetre on an individual panel

- the defect could not be noticed prior to the installation of the floor

- the defect is reported in writing within 30 days of it being noticed

- Krono Original or their appointed representative is allowed to check the defective floor on site

Within the scope of this warranty, Krono Original has the option to:

- repair the floor at no charge or

- reimburse the current value of the floor or

- deliver to the original point of sale any replacement material up to the current value* of the defective floor. If the original decor is not available, a suitable replacement will be delivered. Any installation costs are to be borne by the customer

* The current value is the original purchase price reduced for each 12 month period which has elapsed since the purchase of the floor, the reduction calculated on a straight line basis so as to reduce the original purchase price to zero over the period of the warranty.

Any warranty claim which is accepted does not prolong the warranty period of the original floor.

Other exclusions:

The warranty described above will not apply and we will not in anyway be liable in the event of:

- Misuse - No responsibility will be accepted for any damage caused directly or indirectly through misuse, abuse, accident or use that is not consistent with the Krono Original installation instructions. No guarantee either express or implied is given for any damage due to inadequate care or other causes including without limitation, extreme heat or from moisture caused by wet mopping, spills or standing water.

- Alterations or repairs - Alterations and unauthorised repairs to any Krono Original flooring will void any and all express or implied warranties including merchantability or fitness for purpose.

- Reinstallation - In the event that we replace defective boards, we shall not be liable to provide for or incur the costs of removing or reinstalling the defective floor. No liability to replace or repair shall extend to any sub-floor materials or any other items used in the course of removal, installation or refinishing.

This warranty is not transferable and is extended only to the original purchaser and for the original installation. All warranties shall expire on sale, transfer or relocation of all or any part of the installed floor.

Liability limitations:

Except as stated herein no other warranty, express or implied, is provided including any warranty of fitness for a particular purpose. No retailer, installer, dealer, distributor, agent or employee has authority to increase the scope or alter the terms or the coverage of this warranty. No agreement to repair or replace shall in any event act to extend the period of coverage of any warranty provided. In no event shall we be liable for any claim loss or damage arising from the purchase, use or the inability to use its products or from any form of special, indirect, incidental, or consequential damages including, without limitation, lost profits, emotional, multiple, punitive or exemplary damages, or legal fees. In no event shall we be liable for the costs of old or new materials other than Krono Original floors. In no event shall our liability exceed the amount we actually received for the sale of the defective materials concerned. All claims must be in writing and in order to make a claim under this warranty, evidence of the purchase date and the identity of the original purchaser and installation location must be provided. Without such proof, no warranty shall apply.

A stunning light beige almost grey oak 8mm thick laminated floor, produced from FSC and PEFC-certified sustainably-managed forests in one of the most advanced factories in the world using the latest technology. Just what you need to impress the neighbours!

This light oak 8mm laminated floor with its authentic embossed surface and deep matt grain, faithfully reproduces the most exquisite features of premium quality timber, giving a natural look and feel to a room. Flooring is crucial - it sets the tone as soon as you enter a room and this floor does just that. Laid as a floating floor with no need for any bonding to your sub-floor and cleverly engineered to provide strength and stability with its high-density fibreboard core, its profiled edges enable anyone to lay this floor absolutely perfectly every single time, just like a professional would!

Key features:

- £28.78 per pack including VAT - £23.98 per pack excluding VAT

- 1288mm x 195mm x 8mm board - New size

- 9 boards in a pack = 2.26 square metres coverage - New pack quantity

- Planked authentic embossed satin surface finish

- Laid as a floating floor so no need for any adhesive

- 20 year guarantee for domestic use

- 5 year guarantee for commercial use

- Four-sided V-groove bevelled edges

- Suitable for heavy domestic use and general commercial use

- Really easy to install - the boards simply click together

- So easy to maintain

- Suitable for under-floor heating

- See below for all accessories available with this floor

| Board specification | |

| Krono 1Clic2Go interlocking joint | Yes |

| V-shaped bevelled edge on all four sides | Yes |

| Surface | Planked authentic embossed satin surface finish |

| Anti-static properties | Yes |

| Coreboard | High-density fibreboard (HDF) |

| Board size | |

| Board size | 1288mm x 195mm |

| Board thickness | 8mm |

| Pack size | |

| Boards per pack | 9 |

| Area per pack | 2.26 square metres |

| Pack weight | 15kg |

| Pallet size | |

| Packs per pallet | 48 |

| Area per pallet | 106.6 square metres |

| Installation | |

| Floating floor | Yes |

| Interlocking joint | Yes |

| Underlay required | Yes |

| Finishing items | |

| Matching door threshold trims | Yes |

| Matching 2400mm x 19mm x 19mm scotia beading | Yes |

| White 2440mm x 15mm x 15mm scotia beading | Yes |

| Technical | |

| Abrasion class | AC4 |

| Wear class for domestic use | 23 - heavy domestic use |

| Wear class for commercial use | 32 - general commercial use |

| Warranty | |

| Warranty for residential use | 20 years - see terms and conditions |

| Warranty for commercial use | 5 years - see terms and conditions |

Krono Super Natural Boulder Oak laminated floor

- Brands Krono Original

- Product Code: 5542

- Availability: In Stock

-

£12.74 /m²

- exc VAT: £10.61 /m²

Related Products

3mm UL12 Silver Ultra underlay

A standard polyethylene foam underlay with a built-in vapour barrier, ideal for all laminate floors!..

£27.98 /roll exc VAT: £23.32 /roll

White Scotia Beading

A white scotia beading for the perfect finishing around your floor, ideal for all laminate floors!Si..

£4.50 /length exc VAT: £3.75 /length

Matching Scotia Beading

A matching scotia beading for the perfect finish around your floor, available for most laminate floo..

£4.50 /length exc VAT: £3.75 /length

Matching 'T' Section

A matching 'T' section, available as an exact match to your chosen laminated floor. The perfect..

£11.14 /length exc VAT: £9.29 /length

Matching Ramp Section

A matching ramp section, available as an exact match to your chosen laminated floor. The perfec..

£11.14 /length exc VAT: £9.29 /length

Matching End Section

A matching end section, available as an exact match to your chosen laminated floor. The perfect..

£11.14 /length exc VAT: £9.29 /length

2mm UL10C White Foam underlay

A standard polyethylene foam underlay, ideal for all laminate floors!This standard polyethylene unde..

£12.90 /roll exc VAT: £10.75 /roll

3mm UL11C Barrier Plus Foam underlay

A standard polyethylene foam underlay with a built-in vapour barrier, ideal for all laminated and en..

£26.20 /roll exc VAT: £21.83 /roll

3mm UL12C Combi Silver underlay

A 3mm polyethylene foam underlay with a built-in vapour barrier, ideal for all laminate floors!This ..

£17.54 /roll exc VAT: £14.62 /roll

5mm UL13C Gold Ultra underlay

A 5mm-thick high-density foam underlay with an aluminium vapour barrier, ideal for all laminate floo..

£46.15 /roll exc VAT: £38.46 /roll

5mm UL14C Foamboard Green underlay

A rigid, dense fibreboard underlay, made from natural fibres and ideal for all laminate floors and B..

£25.00 /pack exc VAT: £20.83 /pack

Tags: Krono, Krono Original,